Web Content Viewer (JSR 286)- Asponte Custom Skin

Web Content Viewer (JSR 286)- Asponte Custom Skin

-

Home

/

-

Technology

/

-

Print Production

/

-

Industrial Printing

/

-

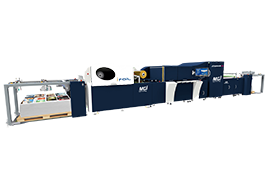

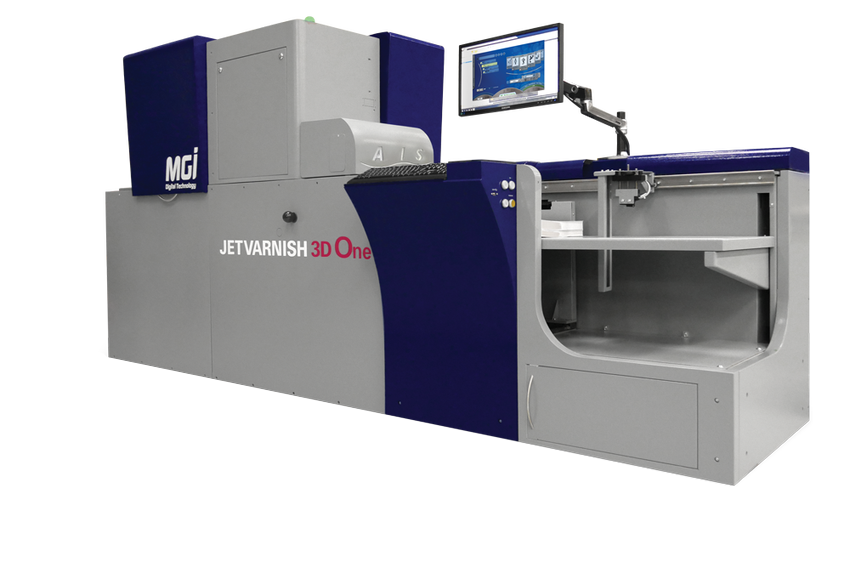

MGI JETvarnish 3D One

MGI JETvarnish 3D One

The JETvarnish 3D One is the most cost-effective point of entry into MGI’s complete series of sheet-fed, digital print enrichment finishing presses. The small operational footprint of the JETvarnish 3D One allows printers, finishers, and converters to have an in-house full production and prototyping print embellishment system without screens, dies or plates. The all-purpose patented varnish formula allows both flat 2D Spot UV highlighting and sculptured 3D raised special effects on a wide range of substrate stocks and media (such as paper, synthetics, plastics). The JETvarnish 3D One creates opportunities for enhancing brand identity, more powerful printed communications and highly profitable digital special effects on all printing applications, such as booklets, brochures, business cards, mailpieces, book & magazine covers, sheet-fed labels, small folding cartons and more!

Key Features

Digital 2D/3D Special Effects Solution

Full automatic varnish registration by AIS SmartScanner

Coats up to 2,077 A3 sheets size per hour

Software Suite supplied for streamlining and facilitating production

Other Features

High Capacity Paper Feed: New vacuum belt feeding system. Able to handle a paper pile up to 11.8” high or approximately 2,250 sheets at 135 gsm. Supports paper formats from Letter up to 14.3” x 29.5”.

Intuitive Operability: Innovative software suite developed by MGI that includes management tools such as: a job cost calculator, workstation image editor, reprinting utility and AIS SmartScanner setup.

AIS SmartScanner: The patented AIS system uses artificial intelligence to create an automatic varnish registration for inkjet heads over the preprinted sheet. It’s fully compatible with variable data (VDP) jobs.

Spot UV Print Engine: Exclusive inkjet engine technology with on-Demand (DoD) piezoelectric print heads provides single pass printing. Depending on file and the substrate used, the coating thickness can vary from a coating of 21 microns (μm) up to 116 μm for 3D raised texture effects and a tactile feel.

Paper Output Tray: Exit tray able to handle approximately 1,250 sheets at 135 gsm.